Exploring the Intersection of 3D Printing and CNC Technology

In the ever-evolving landscape of manufacturing, the convergence of cutting-edge technologies has paved the way for unprecedented innovation. Among these transformative technologies, 3D printing and Computer Numerical Control (CNC) machining stand out as revolutionary tools reshaping the way products are designed, prototyped, and manufactured. This article delves into the synergy between 3D printing and CNC technology, exploring how their integration is revolutionizing manufacturing processes across industries.

|

| 3D Printing and CNC Technology |

Understanding 3D Printing and CNC:

Before delving into their synergy, it's essential to grasp the fundamentals of 3D printing and CNC technology:

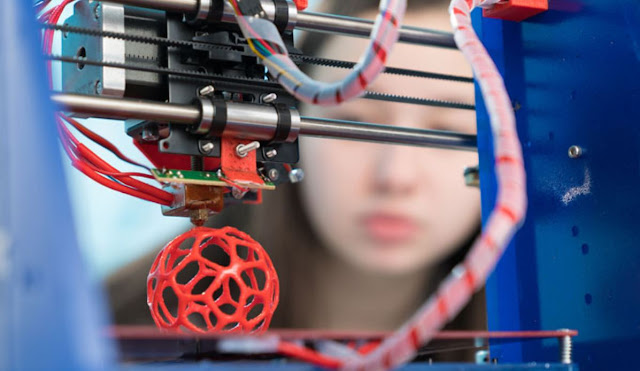

3D Printing:Also known as additive manufacturing, 3D printing builds three-dimensional objects layer by layer from digital designs. This additive process enables unparalleled design flexibility, allowing for the creation of complex geometries and intricate structures with precision and efficiency.

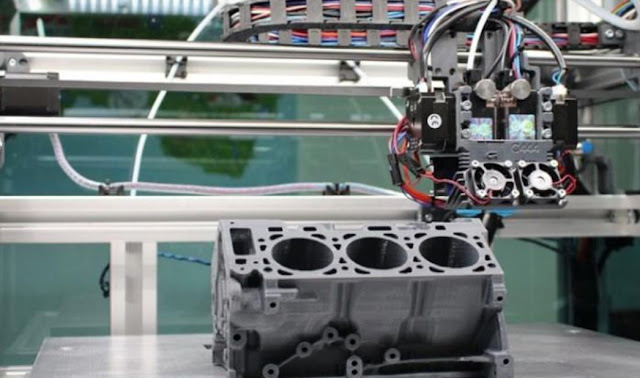

CNC Machining:Conversely, CNC machining is a subtractive manufacturing process that utilizes computer-controlled machines to remove material from a solid block, resulting in the creation of precise and detailed components. CNC machines, equipped with cutting tools, follow pre-programmed instructions to carve out parts from various materials such as metal, plastic, and wood.

The Synergy Unleashed:

While 3D printing and CNC machining have traditionally been viewed as distinct manufacturing methods, their integration offers a potent combination of strengths:

1. Hybrid Manufacturing:The fusion of 3D printing and CNC technology enables hybrid manufacturing processes that leverage the benefits of both additive and subtractive techniques. For example, a part may be initially 3D printed to create complex features, then subjected to CNC machining for surface finishing and dimensional accuracy.

2. Enhanced Precision:By combining the high precision of CNC machining with the intricate detailing of 3D printing, manufacturers can achieve unparalleled levels of accuracy and surface finish. This synergy is particularly advantageous in industries such as aerospace, automotive, and medical, where precision is paramount.

3. Material Versatility: 3D printing and CNC machining support a wide range of materials, including metals, plastics, ceramics, and composites. By integrating these technologies, manufacturers gain access to a diverse palette of materials, each offering unique properties suited to specific applications.

4. Streamlined Production: The integration of 3D printing and CNC technology streamlines the production process, reducing lead times and minimizing material waste. Manufacturers can optimize workflow by leveraging the strengths of each technology, from rapid prototyping with 3D printing to high-volume production with CNC machining.

Applications Across Industries:

The synergy between 3D printing and CNC technology finds applications across diverse industries:

1. Automotive Manufacturing: In the automotive sector, hybrid manufacturing processes are used to produce lightweight components with complex geometries, improving fuel efficiency and performance.

2. Medical Device Production:The integration of 3D printing and CNC machining enables the fabrication of patient-specific medical implants and surgical instruments, enhancing precision and customization.

3. Tooling and Prototyping: Manufacturers utilize hybrid manufacturing for the rapid production of tooling and prototypes, accelerating product development cycles and reducing time-to-market.

4. Customized Production:From consumer electronics to jewelry, the synergy between 3D printing and CNC machining enables the creation of bespoke, personalized products tailored to individual preferences.

The Future of Manufacturing:

As the capabilities of 3D printing and CNC technology continue to evolve, the synergy between these technologies will play an increasingly pivotal role in shaping the future of manufacturing. From on-demand production to sustainable manufacturing practices, the integration of 3D printing and CNC machining holds immense potential to drive innovation, efficiency, and customization across industries.

In conclusion, the convergence of 3D printing and CNC technology represents a paradigm shift in the manufacturing landscape, unlocking new possibilities for design, production, and customization. By harnessing the synergies between these transformative technologies, manufacturers can embark on a journey of innovation, pushing the boundaries of what's possible and ushering in a new era of manufacturing excellence.